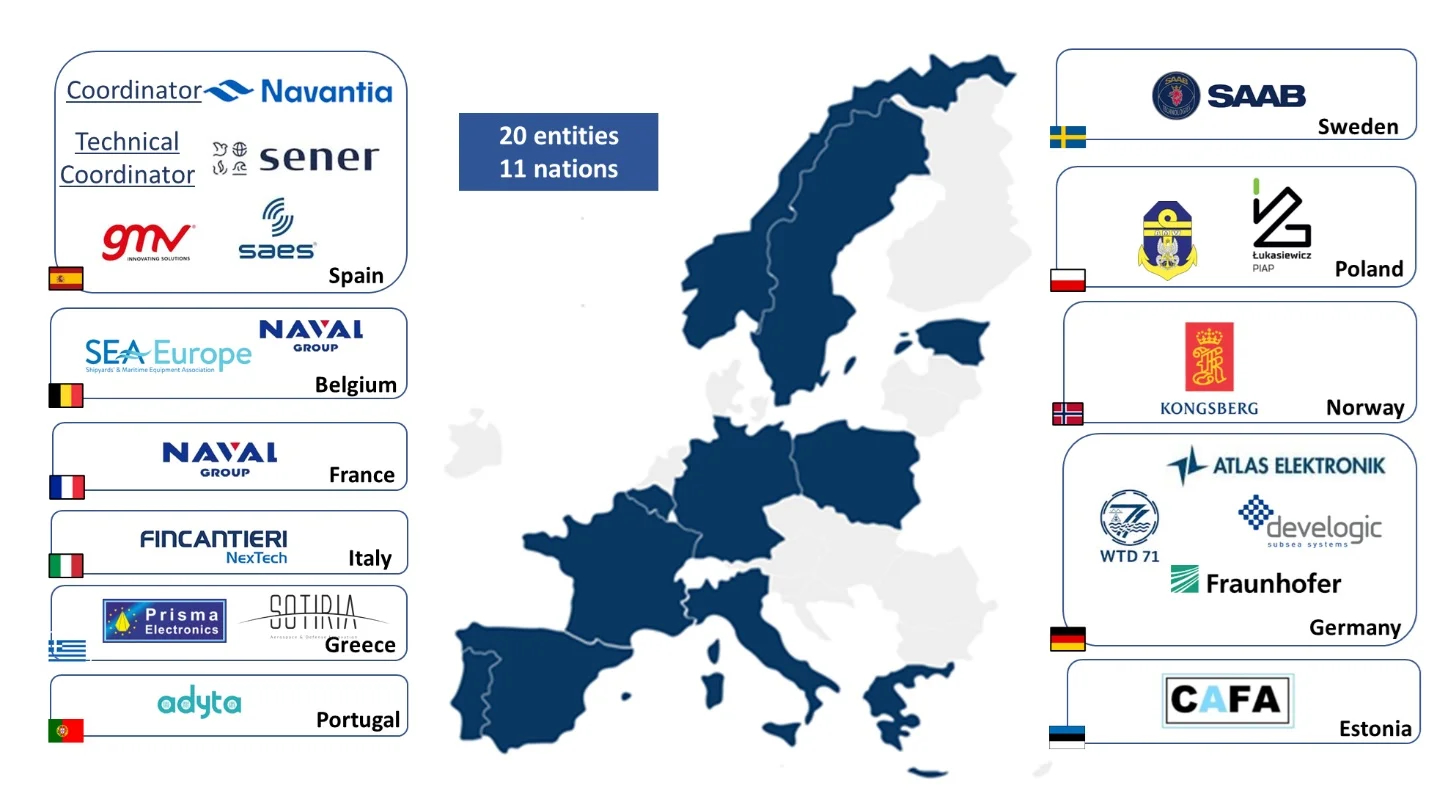

The European Defence Agency (EDA) has launched the AMASM project (Advanced Materials for Acoustic Signature Management), a groundbreaking initiative aimed at developing advanced materials that can reduce noise emissions from naval platforms, such as submarines and unmanned underwater vehicles. The kick-off meeting for the AMASM project, which sees SAES collaborate with the Naval and Sea Technological Centre (CTN), took place on 27th May at EDA’s headquarters in Brussels. The project’s aim is the selection and evaluation of advanced materials for effective acoustic signature management.

On 27th May, the EDA’s facilities in Brussels hosted the inaugural meeting of the AMASM project, which is focused on the selection and evaluation of advanced materials to make naval platforms quieter, safer, and harder to detect during critical missions. Representing SAES at the launch were Diversification Manager, Eduardo Ruiz, and the R&D and European Projects Manager, Antonio Sánchez.

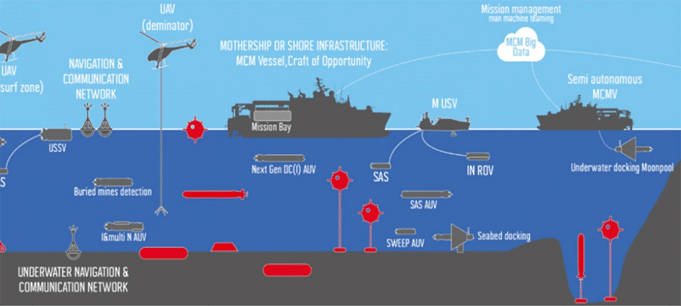

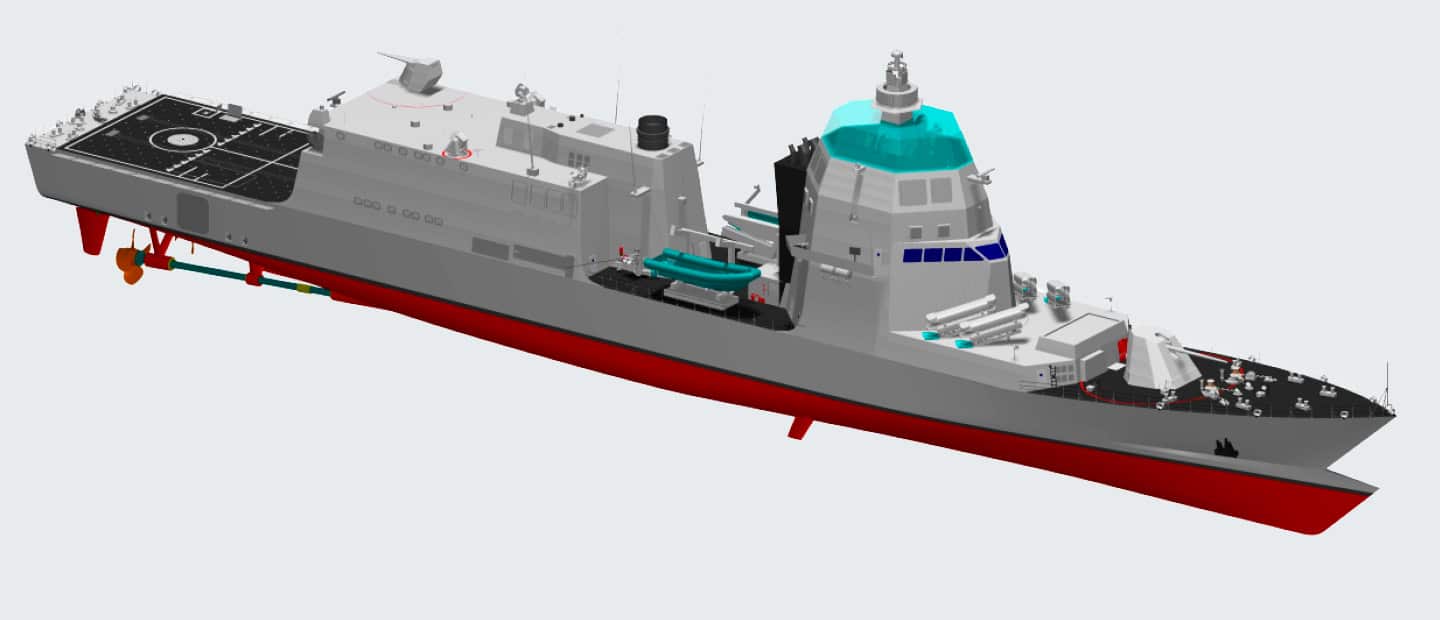

The AMASM project (Advanced Materials for Acoustic Signature Management), was awarded to a Spanish consortium led by Naval and Sea Technological Centre (CTN), with collaboration from SAES, SRG, and FABITIVE, following its selection in tender 24.RTI.OP.210, open to the 27 EU member states of the EDA. This project will facilitate the development and application of new materials to reduce, control, or manage the acoustic signals emitted by military platforms—such as submarines, vessels, or naval drones—both passively (through sound absorption or dispersion) and actively (using noise-cancellation technologies).

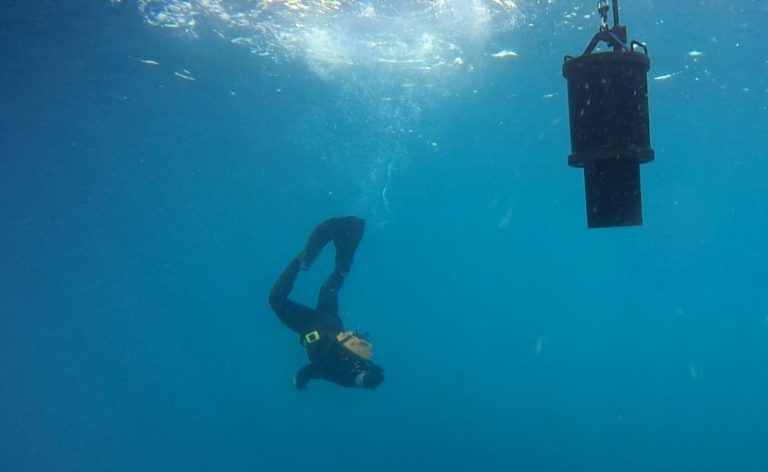

The project is structured into three phases, each lasting 12 months. The first phase will focus on developing a validated proof of concept that aligns with European defence priorities and supports a sustainable supply chain for advanced materials. The second phase will tackle the design and validation of a prototype, which will be finalised and tested in a controlled environment during the final phase. This last phase will consider aspects like performance, durability, and manufacturing ease.

SAES’s involvement focuses on the phases involving the definition of operational concepts and system testing, particularly leading the effort to define use cases in the defence sector, especially within marine environments. This work will underpin the design phases of the material prototypes, which will undergo laboratory testing.